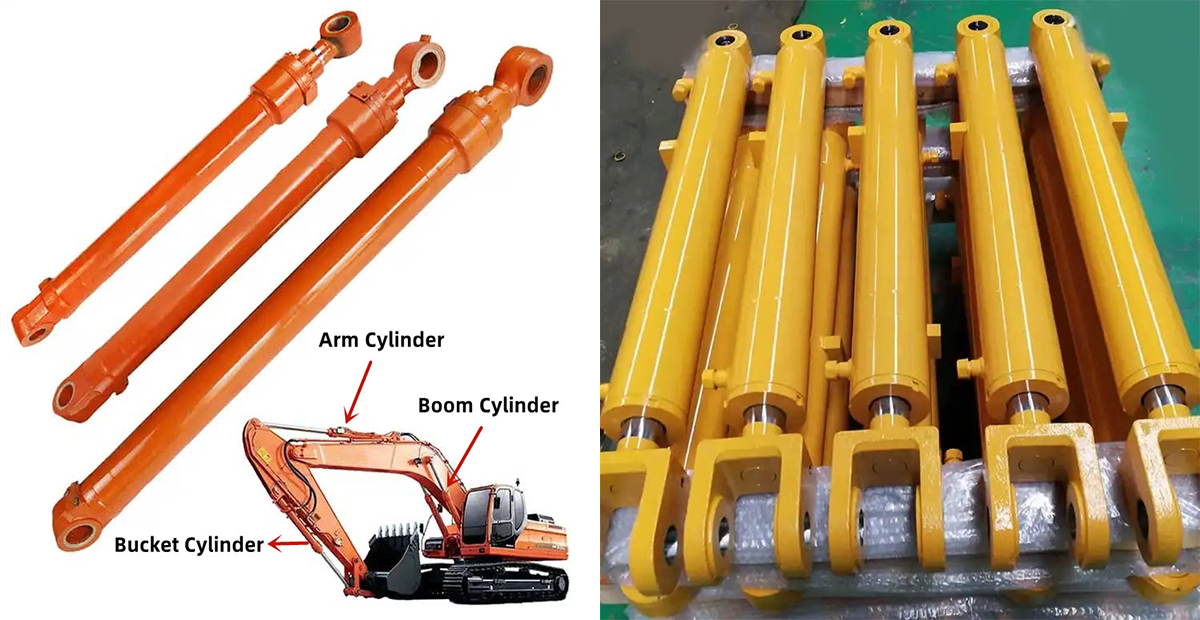

Hydraulic Cylinder Introduction

Oil cylinder generally refers to the hydraulic cylinder. Hydraulic cylinder is a hydraulic actuator that converts hydraulic energy into mechanical energy and does linear reciprocating movement (or swinging movement). It is simple in structure and reliable in operation. When it is used to achieve reciprocating movement, the deceleration device can be eliminated, and there is no transmission gap, and the movement is smooth, so it is widely used in various mechanical hydraulic systems. The output force of the hydraulic cylinder is proportional to the effective area of the piston and the pressure difference between the two sides; The hydraulic cylinder is basically composed of cylinder and cylinder head, piston and piston rod, sealing device, buffer device and exhaust device. Buffer device and exhaust device depending on the specific application, other devices are essential.

1. How to choose a high-quality cylinder?

In order to choose the products suitable for the PC200-3 arm cylinder, there are mainly two reasons: first, clearly understand the use needs, and determine the price range of the product that it can afford to further narrow the range of choices; The second is to choose a professional and regular manufacturer, which can ensure product quality and product performance, and then ensure that the product has a good use effect.

2.Why temper the piston rod in the cylinder?

The purpose of quenching and tempering the piston rod in the CAT E312 boom cylinder is to make the piston rod have higher strength and hardness, better plasticity and toughness, and good comprehensive mechanical properties, and have a good effect on the subsequent surface hardening. Prepare the organization. For pressure, the effective area of the cylinder is the calculated thrust, which is obtained by multiplying the pressure by the area.

3.Cylinder is the main part of construction machinery, the traditional processing method is: broaching cylinder block – fine boring cylinder block – grinding cylinder block. The rolling method is: broaching cylinder block – fine boring cylinder block – rolling cylinder block, the process is 3 parts, but the time is compared: grinding 1 meter of the cylinder block is about 1-2 days, rolling 1 meter of the cylinder block is about 10-30 minutes. Input comparison: grinding machine or quilting machine (tens of thousands – millions), rolling knife (ten thousand – tens of thousands). After rolling, the surface roughness of the hole decreases from RA3.2-6.3um before rolling to RA0.4-0.8&um, the surface hardness of the hole increases by about 30%, and the fatigue strength of the inner surface of the cylinder increases by 25%. If the service life of the cylinder is only considered, it is increased by 2 to 3 times, and the efficiency of the boring and rolling process is about 3 times higher than that of the grinding process. The above data show that the rolling process is efficient and can greatly improve the surface quality of the SH120 bucket cylinder.

After the cylinder is rolled, there is no sharp tiny edge on the surface, and long-term motion friction will not damage the seal ring or seal, which is particularly important in the hydraulic industry.